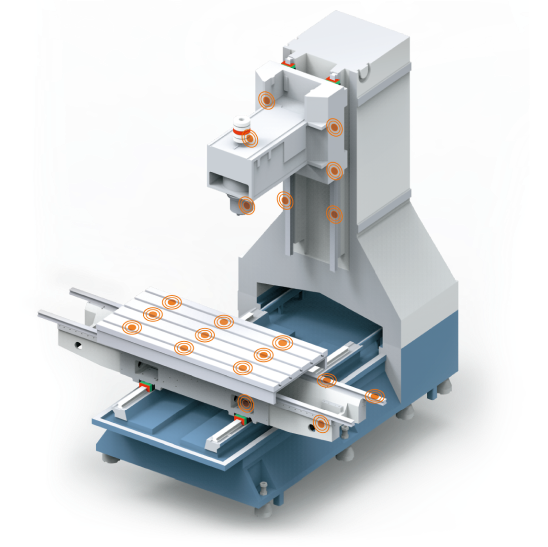

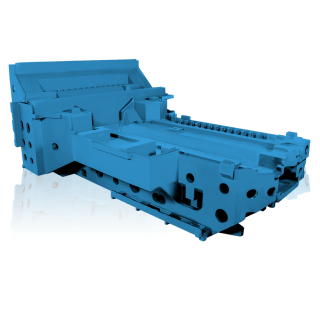

Intelligent Monitoring

Artificial Neural Sensing

Place neural sensors into casting structure to sense information about vibration, temperature, deformation, and acceleration.

Place neural sensors into casting structure to sense information about vibration, temperature, deformation, and acceleration.

Information Transferring and Gathering

Gather information about machine health continuously for 24 hours with a delivery of amount of information up to 100 million units per hour.

Gather information about machine health continuously for 24 hours with a delivery of amount of information up to 100 million units per hour.

System of Compensation/Maintenance Warning

AI Data Feedback

Shipped with Chase artificial intelligence(AI), it sets up and determines reasons for problems through self learning to provide best solutions.

Shipped with Chase artificial intelligence(AI), it sets up and determines reasons for problems through self learning to provide best solutions.

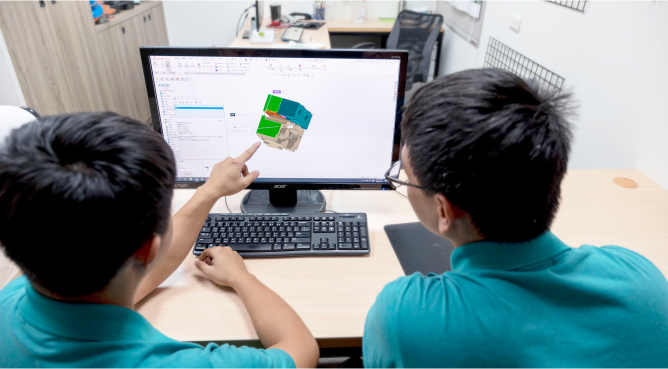

Model Building

Cloud Data Creation

Starting from installation, it inspects status of machine at any time during each use phase and simulate user behavior to establish a unique and exclusive machine system.

Starting from installation, it inspects status of machine at any time during each use phase and simulate user behavior to establish a unique and exclusive machine system.

Open Data Architecture

The Chase smart casting platform also adopts an open data architecture, and can develop APP by itself to use a huge database.

The Chase smart casting platform also adopts an open data architecture, and can develop APP by itself to use a huge database.